Quenching Is the rapid cooling of a workpiece in water, oil, polymer, air, or other fluids to obtain certain material properties. A type of heat treating, quenching prevents undesired low-temperature processes, such as phase transformations, from occurring. It does this by reducing the window of time during which these undesired reactions are both thermodynamically favorable, and kinetically accessible; for instance, quenching can reduce the crystal grain size of both metallic and plastic materials, increasing their hardness.

QUENCHING

Quenching made easy: Choose NUTEC Bickley for customized solutions

Quenching

Definition

When are Quenching tanks used?

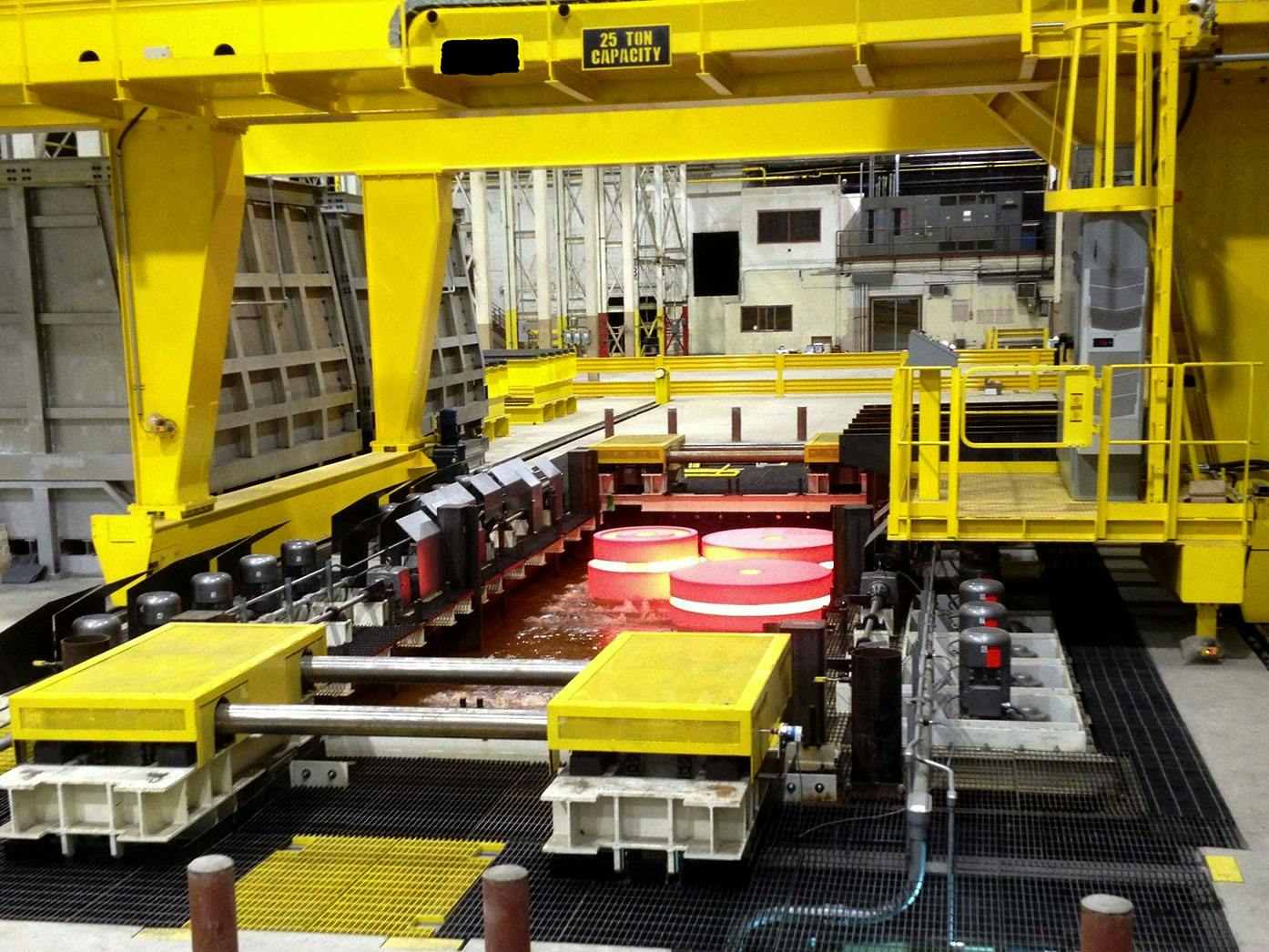

Quenching tanks are used for cooling the parts in water, oil or polymer after the quenching heat treatment process has ended. These are typically paired with a batch style furnace. In a box furnace operation the quench would be placed directly in front of the furnace and the system is comprised of and elevator platform with a roller conveyor.

The same system can be paired with a roller hearth or pusher furnace for continuous operation. Large quench systems can be designed to be partnered with car bottom furnaces. In this arrangement the quenching furnaces are offset to allow the furnace car to travel and then be unloaded by overhead crane or fork transfer mechanisms. They are manufactured in a wide variety of sizes and intended for intensive use.

Applications

Quench tanks for steel castings and forgings

Air quenching for steel castings and forgings

Tank elevator systems

Quenchant agitation

Quench tanks for aluminum casting

Spray

Air quenching chambers for aluminum castings

Batch Quenching Furnaces

- The size of a batch immersion quench tank depends on the dimensions of the workload, as well as the allowable temperature rise.

- The temperature rise permitted is dependent on whether the quenchant is oil, water, or polymer. Care should be taken in a batch operation to ensure that a sufficient amount of quenchant covers the top of the workload.

- The physical dimensions of the tank should be large enough to ensure full immersion of the quench load and fixtures and, at the same time, allow enough space for agitators and manipulators.

- When using hot quenching oils, it is necessary to make an allowance for thermal expansion of the oil, either by making provision for an overflow system, or by manual adjustment of the fluid level.

- A quench tank must contain sufficient fluid to quench the load without an excessive rise in temperature of the quenching fluid.

- To obtain maximum efficiency from cooling systems, the direction of circulation should be such that hot quenchant is removed from the top of the tank and then passed through the heat exchanger.

Air Quenching Systems

- NUTEC Bickley manufactures air quenching systems. This mechanism is used to limit the residual stresses as well as the brittleness that occurs during the quenching process.

- Air quenching can provide aggressive cooling rates without the side effect of distortion and eliminate the need for subsequent straightening processes.

- Air quenching is a good choice when quenching parts with dissimilar metals such as aluminum engine blocks with cast iron bore liners. Another advantage to implementing an air quench is the low distortion rate.

- Water quenching is very aggressive on thin walled castings such as shock towers.